Description

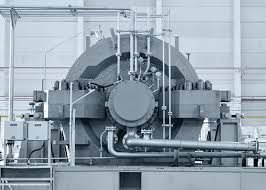

Process gas screw compressors have capacity and pressure capabilities between those of centrifugal and reciprocating compressors. They handle inlet volume flows up to approximately 100,000 m3/h and discharge pressures up to around 70 bar g. They achieve positive displacement compression using two synchronized, helical rotors. Their smooth-running feature, relatively compact design and their tolerance to polymers formation in the casing or on rotors (unlike centrifugal or reciprocating compressors), make them an optimum solution for the following processes, especially in oil & gas production, oil refining and petrochemical processing:

- Difficult gasses (dirty, polymer-forming, liquid containing, corrosive)

- Gasses containing entrained liquids

- Corrosive gasses

- Process that fluctuate in molecular weight, pressures and flow rates

- Low molecular weight gasses

In particular, dry screw gas compressors are suitable for complex and dirty gas services, such as offshore vapor recovery, refinery flare gas recovery and petrochemical polymer forming gas, which make them an excellent choice for handling dirty gasses.